When buying your next overhead crane, don’t forget to ask to what standards and what process your crane will be wired.

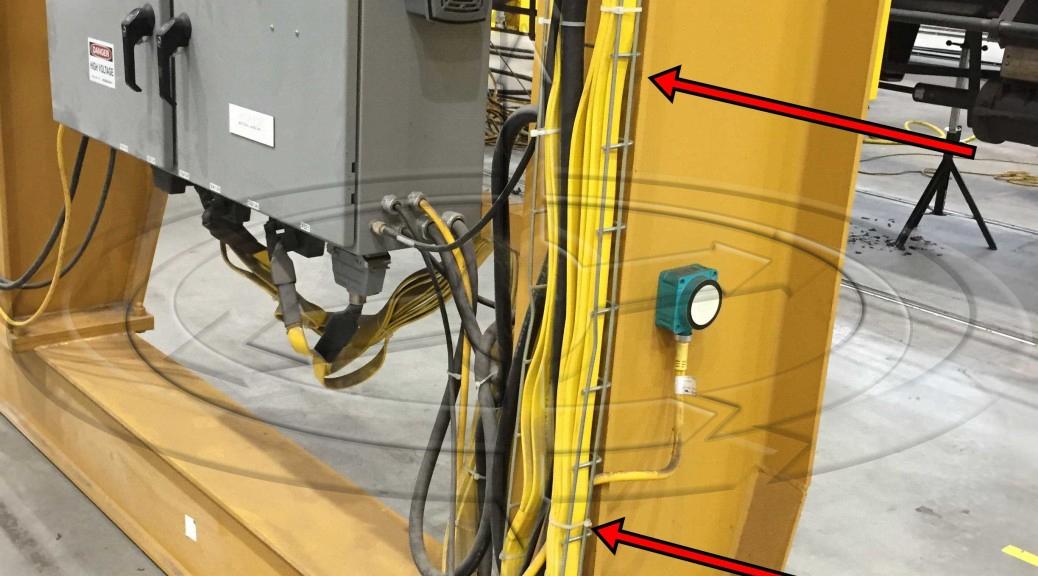

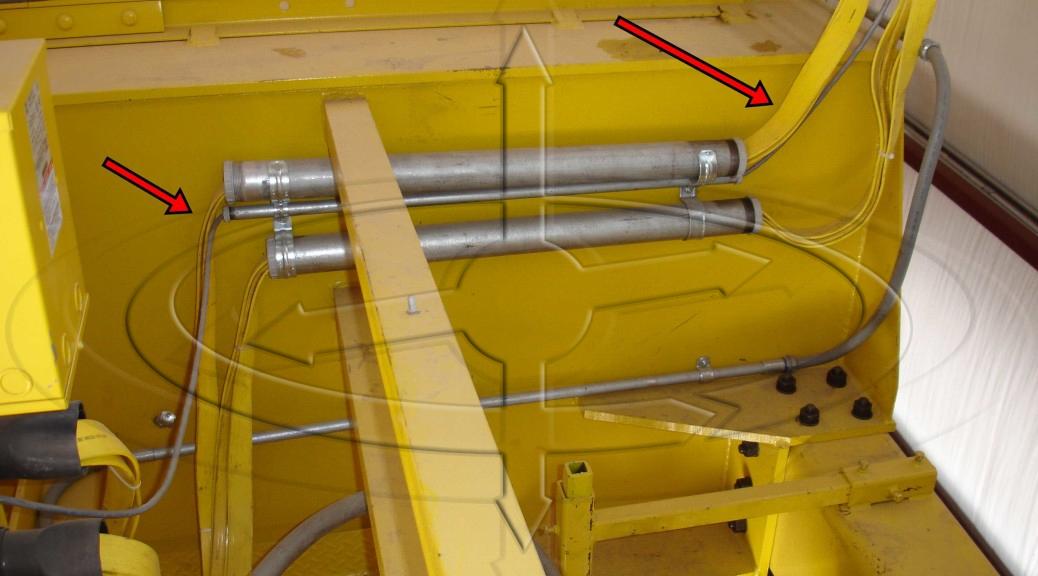

More and more today we are seeing overhead crane manufacturers use flexible conductors for transmitting power and control voltages for extended distances on overhead cranes, gantrys, jibs, and monorails. These flexible conductors such as flat wire festoon conductors, S.O. cord and extended runs of Seal Tite might not be what you wanted on your next crane.

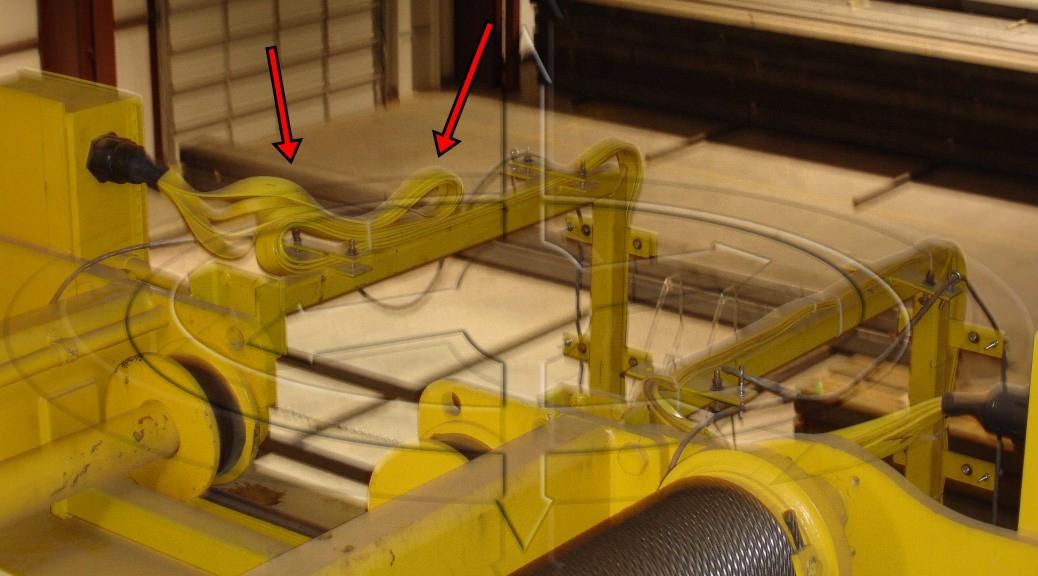

The above pictures show the extended use of flat wire festoon conductors as a method of “hard wiring” on the gantry. These conductors are subject to impact from larger loads carried in the aisle.

When you asked for your crane wiring to be in rigid conduit, was this what you had in mind?

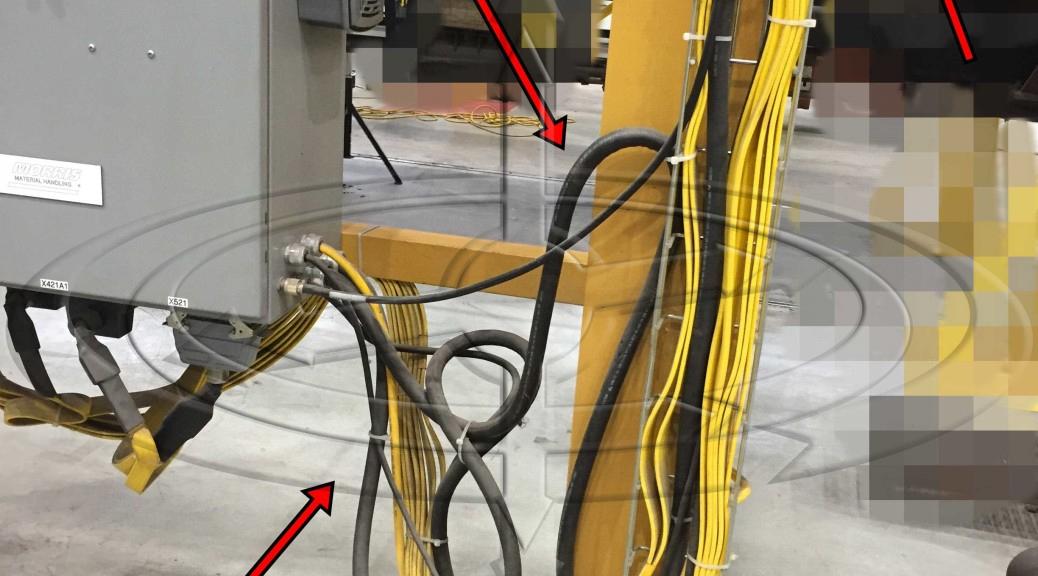

This turns out to be a mess with flat wire festoon conductors wrapped on top of themselves with a zip tie.

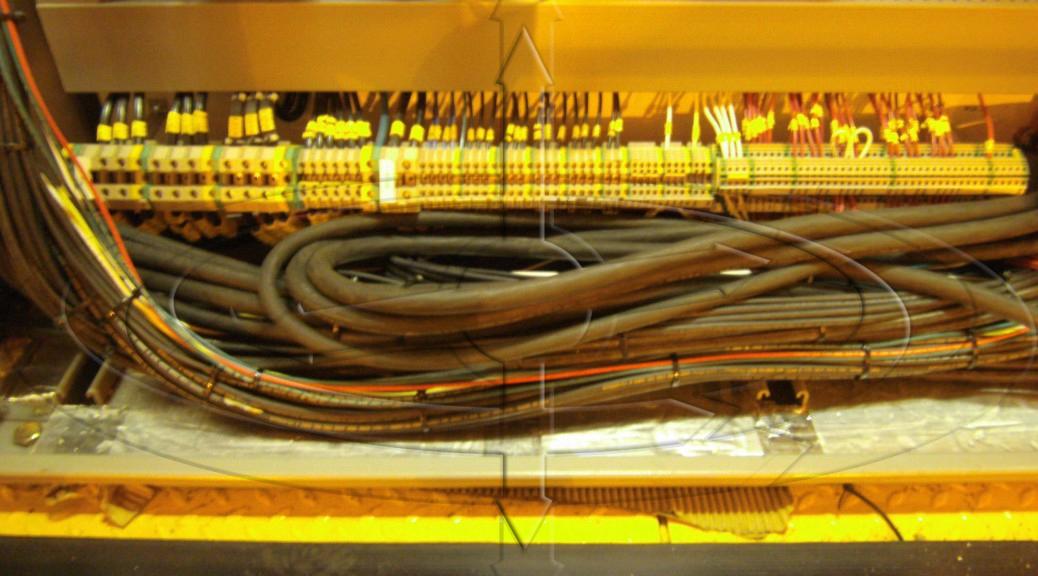

Certainly when a crane is ready to be placed in service you do not want the loose conductors in the panel blocking the terminal strip.

You as the customer can specify the wiring that you are expecting. Indicate if you want EMT, rigid or even PVC conduit, the type of wire (THHN, SMRL, etc…) and limit the use of Seal Tite to a distance (example 18 inches). Wording limiting the use of festoon conductors to only the festoon system, and S.O. cord.

Remember to inspect your overhead crane purchase after its installation and start-up!

If you have any questions just call or write your Crane Doctor, Eric Brown at ebrown@engineeredlifting.com.

Recent news posts

Gravity Latch with Rotation Lock

Magnetek Series 3 Drives Using “Motor 2” Option

Magnetek Brake Circuit Fusing

Crane Cab Replacement Improves Function